Teknika Plast Industrial

40.000

Area m²100+

Plastıc Injectıon Machınes3000+

Standard Packagıng SolutıonsTeknika Industrial

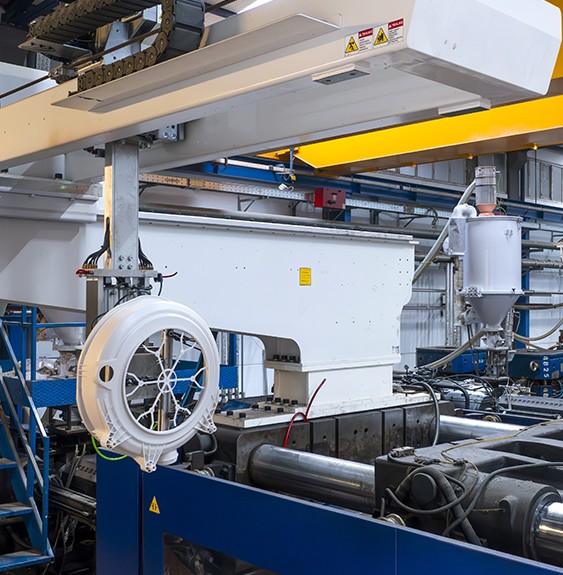

Teknika Industrial manufactures all plastic components for household appliances such as refrigerators, ovens, TV remotes, washing machines and dishwashers.

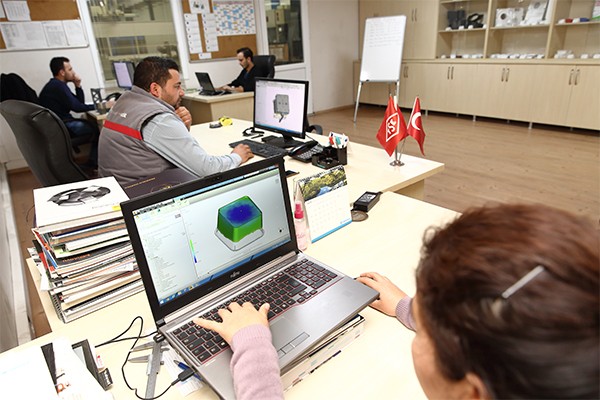

WE ADAPT TO THE REQUIREMENTS OF THE DIGITAL AGE

Teknika Industrial; Plastic Solutions and Contract Manufacturing Specialist

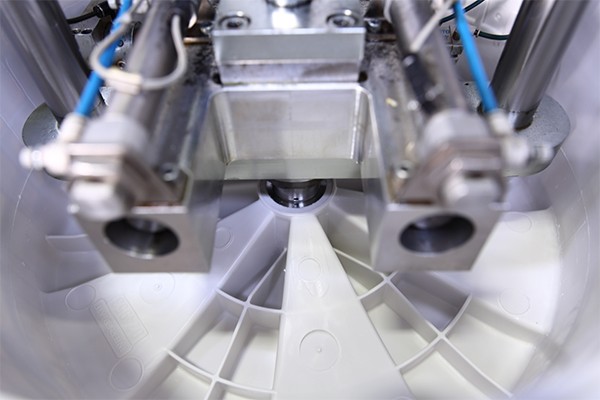

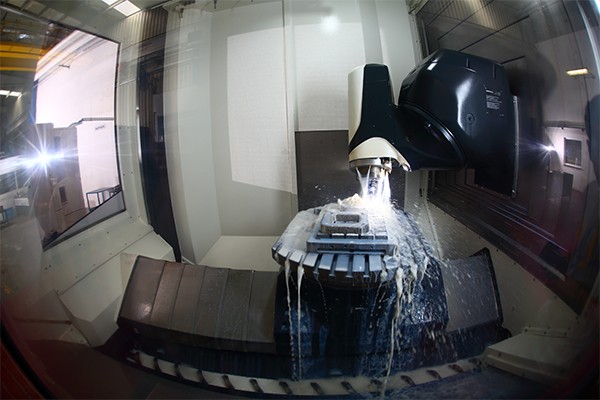

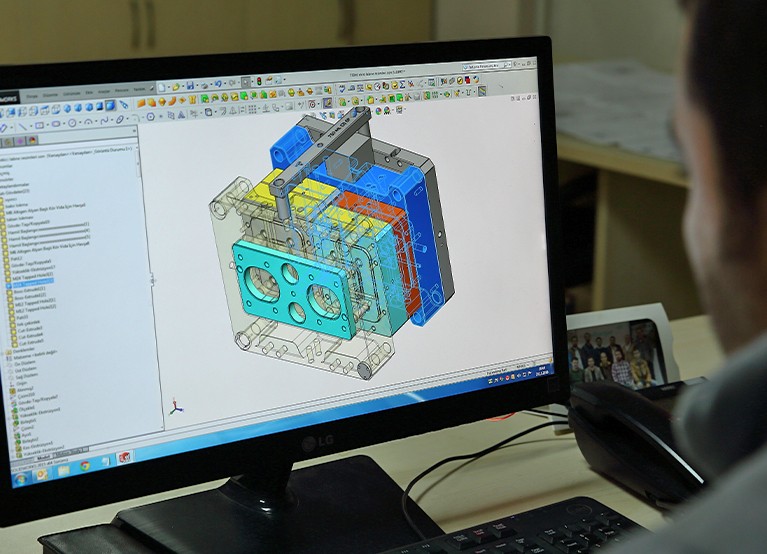

Teknika Endüstriyel offers plastic injection molding and contract manufacturing solutions with over 25 years of experience in the plastics industry. It produces high quality parts for white goods, home heating and plastic household appliances. Advanced engineering is utilized in design and production by offering services such as In Mold Labeling (IML) and In Mold Decoration (IMD) for high quality part decoration.

Products

Quality

01. Humidity Analyse Device

As Teknika Plast, we meticulously perform moisture analysis to guarantee the quality of the plastic parts we produce. Since moisture is a factor that directly affects the physical and mechanical properties of plastic materials, these analysis processes are critical to our production quality.

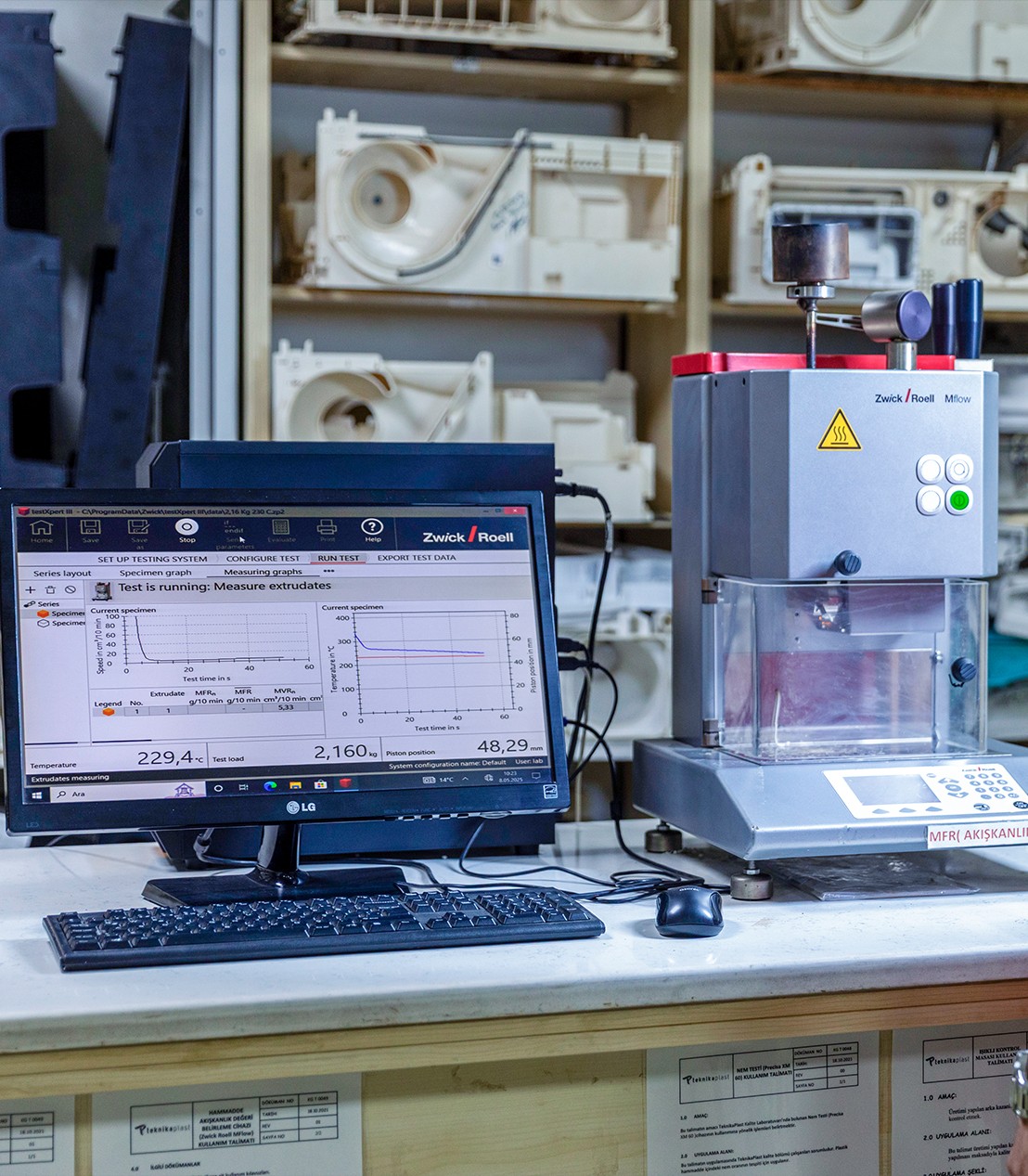

02. Melding Fluidity Test Device

As Teknika Plast Industrial, we apply the melt fluidity test (Melt Flow Index - MFI) to ensure the quality and processability of the plastic parts we produce for the white goods sector. This test determines the fluidity properties of plastic materials in the molten state, helping us optimize our production processes and ensure the quality of the final products.

03. Color Control Device

04. Flammability Test Device

05. Certificates

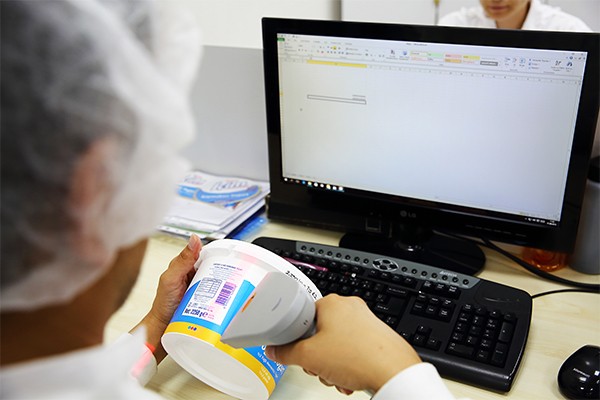

06. Weight and Measurement

We implement a meticulous weight and measurement control process to ensure that the plastic products we produce comply with quality and standards. This process guarantees that our products are produced in the specified diameters and grammages.

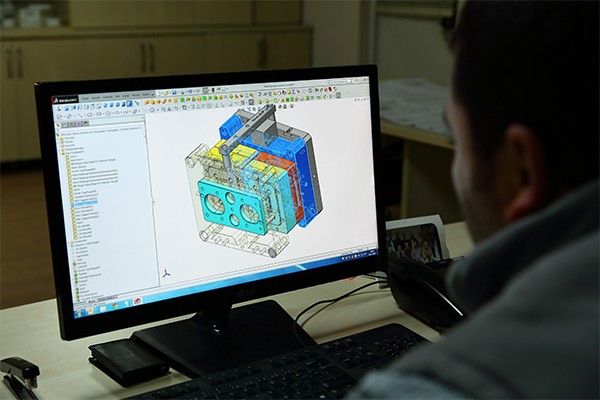

07. CMM

Quality Control Process with CMM Technology

As Teknika Plast Industrial, we use CMM (Coordinate Measuring Machine) technology to maintain the highest level of quality at every stage of our production processes. This technology allows us to meticulously check whether the products produced are compatible with the technical drawings, both during and after the production process.