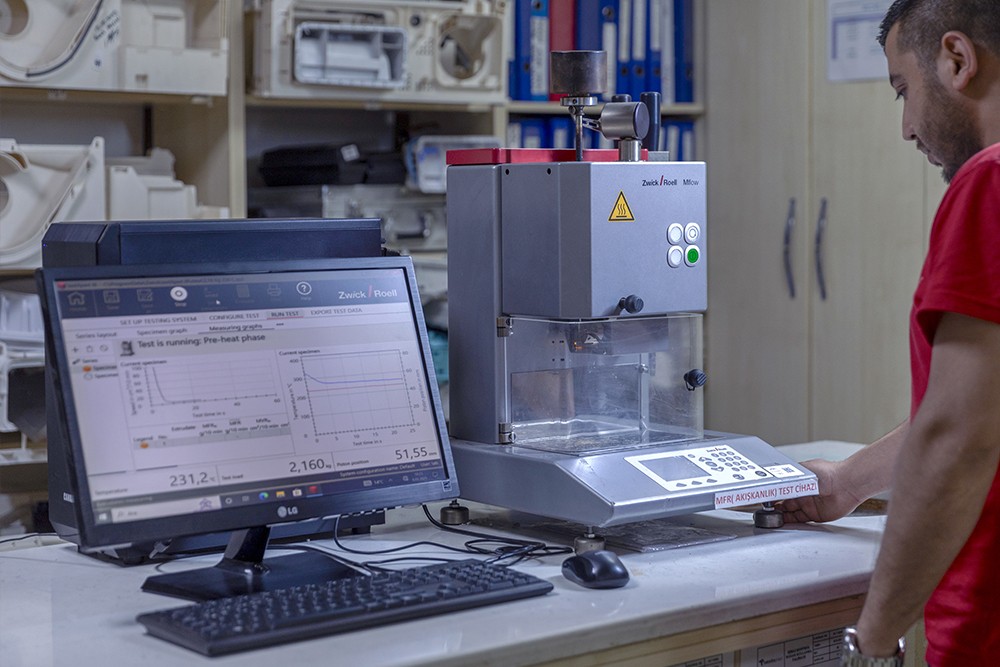

Melding Fluidity Test Device

Melt Flow Test

Melt flow testing is a method that measures the flow rate of thermoplastic polymers in the molten state under a specified temperature and load. This value provides important information about the viscosity and processability of the polymer. The test is usually performed in accordance with ASTM D1238 and ISO 1133 standards.

Testing Process

1. Sample Preparation: Plastic samples used for testing are prepared in a specific quantity and in a clean manner.

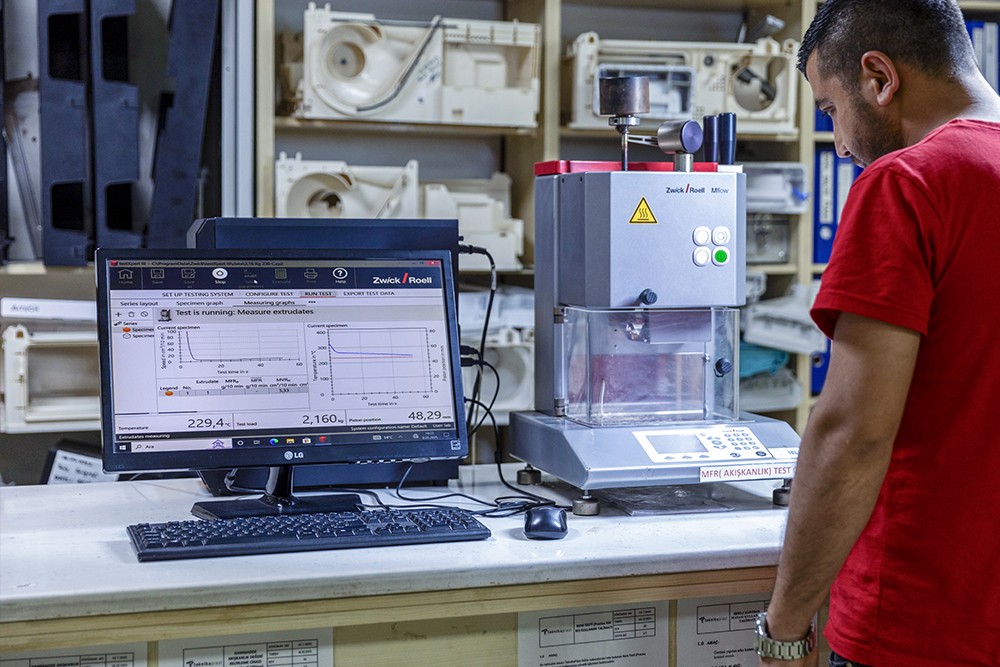

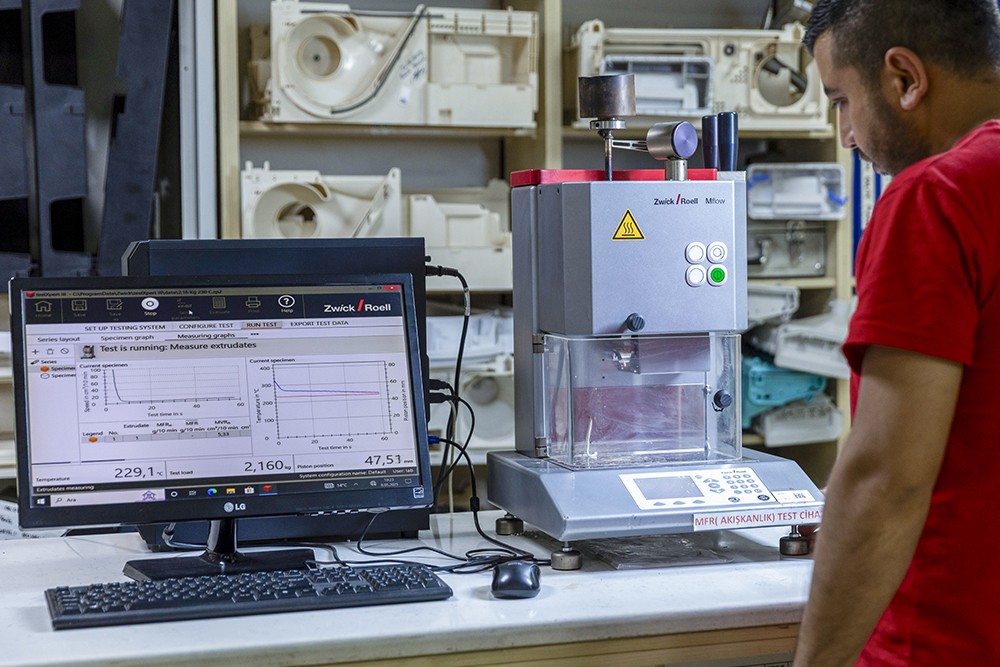

2. Heating: Samples are heated to a specified temperature above their melting point. This temperature may vary depending on the polymer used.

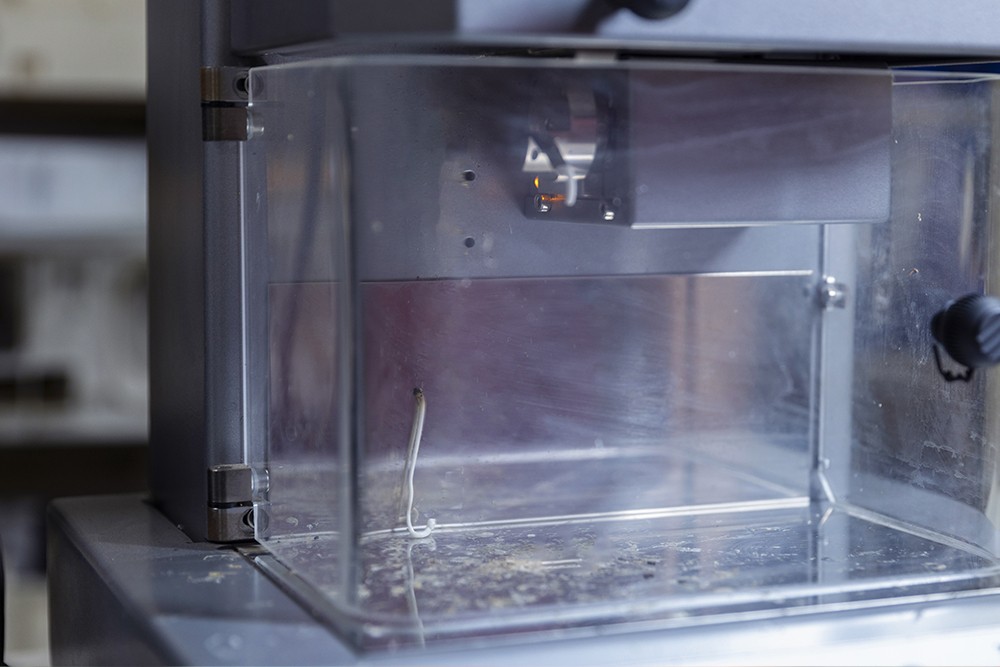

3. Test Application: Heated samples are passed through a standard orifice (hole) under a certain weight and the melt flow rate is measured.

4. Evaluation of Results: The melt fluidity value obtained is used for quality control of the polymer, material comparisons and adjustment of production processes.

• Production Process Control: The melt fluidity value indicates the processability of polymers and their behavior in production processes.

• Quality Assurance: MFI values in accordance with standards ensure the consistency of mechanical and physical properties of products.

• Material Comparison: By comparing the melt fluidity of different polymers, the most appropriate material selection can be made.