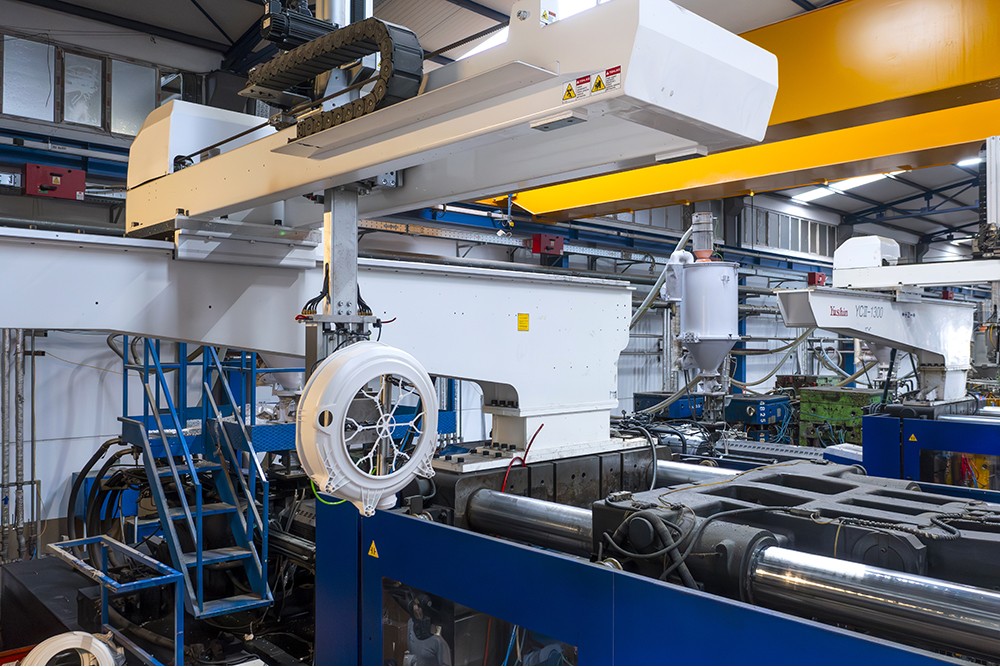

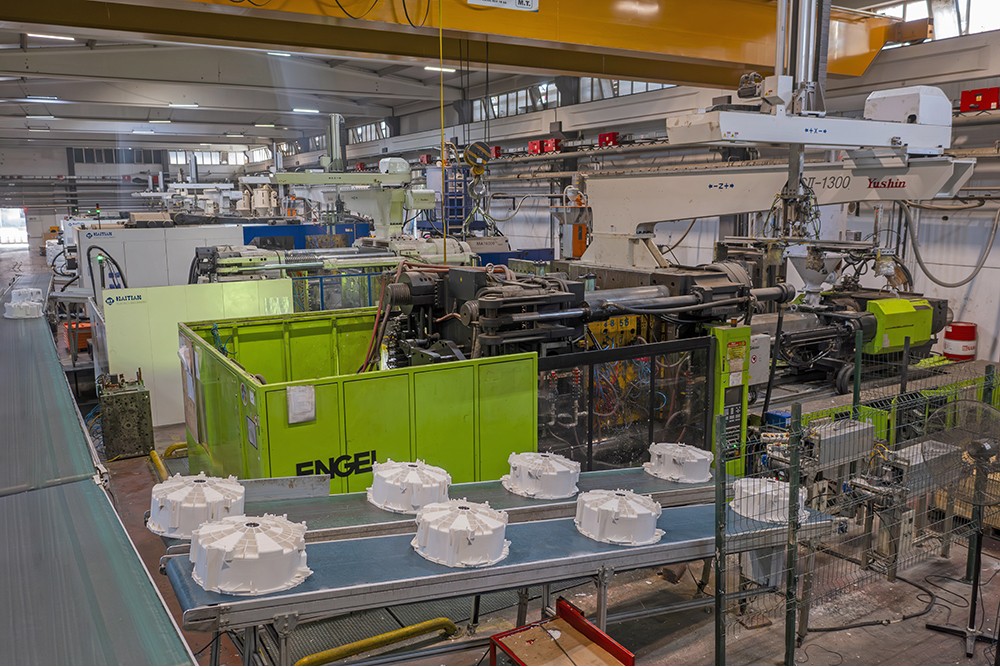

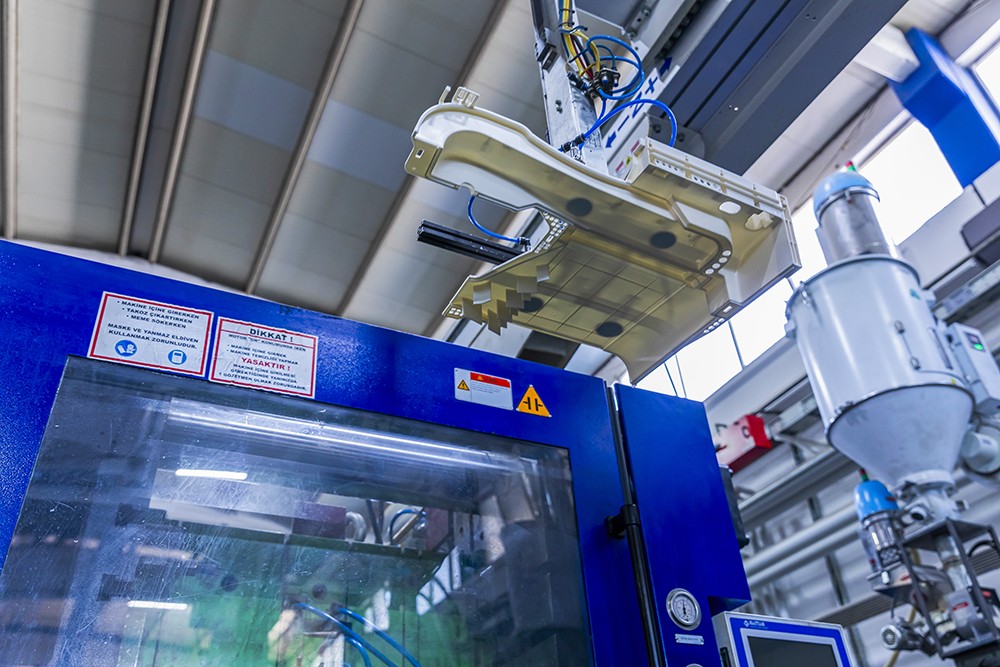

Injection Production

Raw Material

- We have a production capacity of 80 different types of raw materials.

- We can produce using 40 different raw materials at the same time.

- With the automatic feeding system from the silos, the raw materials are supplied accurately and efficiently.

- The masterbatch dosing system ensures that colors and additives are mixed precisely.

Machine and Mold Maintenance

One of the most important features in plastic part production is that we have mold and machine maintenance teams within our organization.

Our mold maintenance team carries out the revision and maintenance operations of molds that need maintenance or urgent intervention thanks to the regular checks it performs. Our mold maintenance area is equipped with experience, technology and product supply to meet all needs.

It also has an active spare parts warehouse for machine maintenance and regular machine maintenance is carried out. In this way, interruptions in production processes are minimized and efficiency is increased.

Express Production

Using our production area correctly and effectively is one of our features that makes us stand out in the sector. After the plastic parts are produced, the necessary personnel and technological investments have been made for the other processes they will enter. By establishing stations such as assembly, vibration welding, ultrasonic welding, pad printing and plasma, we carry out the entire production process in the same area. In this way, we finalize the production quickly and efficiently and complete your products without losing time.

Traceability

- Quality control is continuously performed with a traceable production process and production stages are inspected.

- Raw material needs are determined according to the demands entered in the MRP (Material Request Planning) system and automatic demands are created for missing raw materials

- With the data we collect from the field, we aim to reduce unplanned downtimes to zero by planning the most accurate production on the most accurate machine with automatic schedule “Production scheduling."

MESS System

Every stage in the production process can be monitored with the MESS System and production data collection systems, so quality and efficiency are constantly monitored.

MRP

MRP (Material Request Planning) provides automatic material supply according to the order. Production planning is done with automatic scheduling and each stage of the machines is planned efficiently and production is carried out with high capacity. These integrated processes provide Teknika Plast with an efficient and traceable production flow.