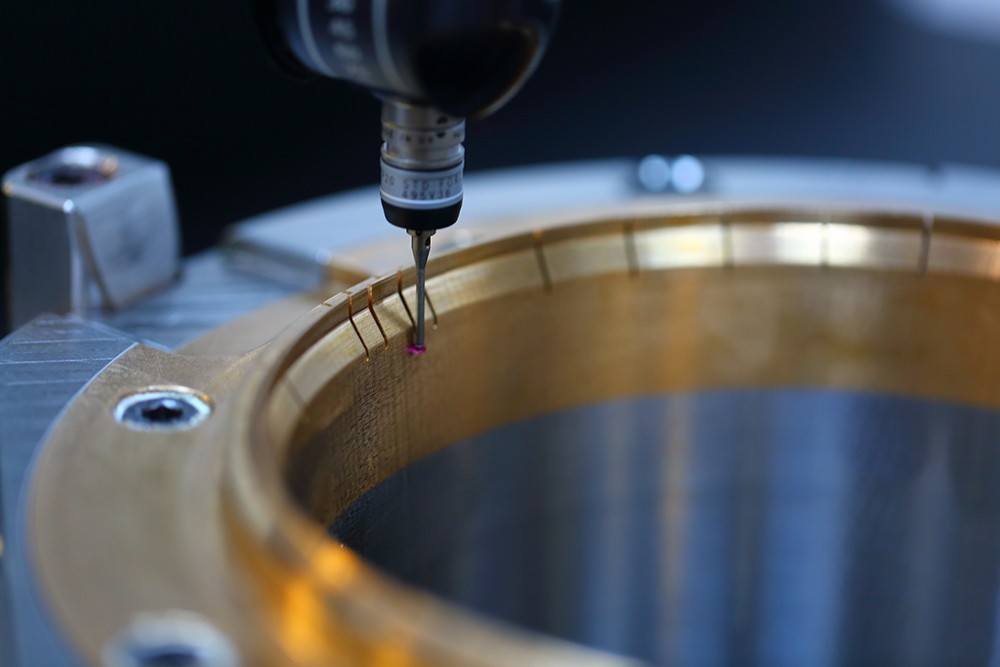

CMM

Initial Sample and Technical Drawing Compatibility Assessment:

The first samples produced are examined in depth using reverse engineering methods. Following this examination, the product’s compliance with the technical drawings is evaluated in detail. The measurement data obtained is reported visually with a color scale and measurement bubbles, thus enabling fast and accurate analysis.

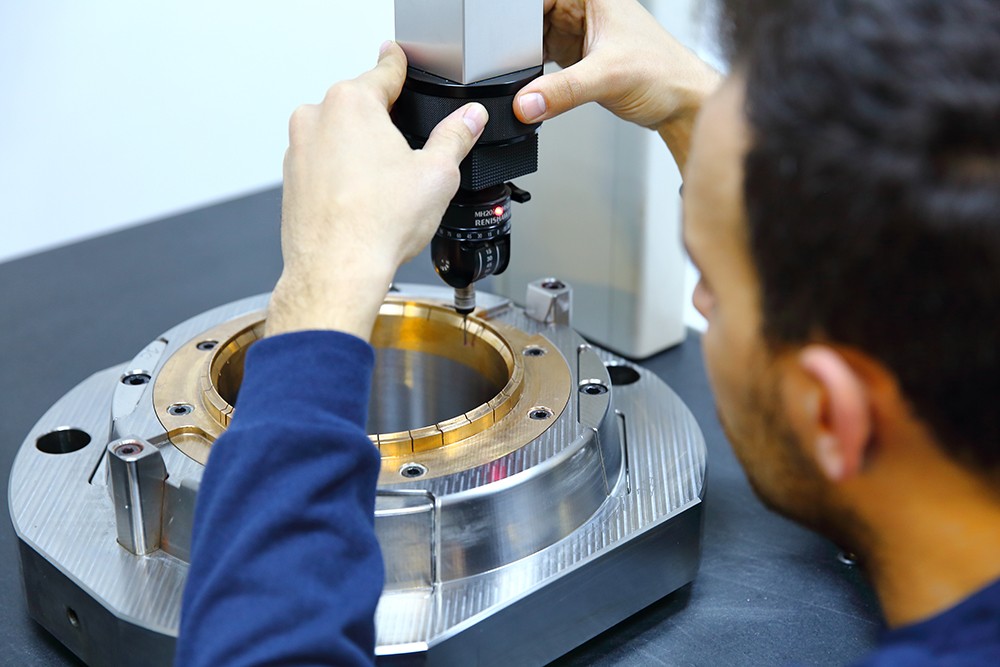

Customer Approval and Mass Production Stage:

The first sample and technical drawing compliance reports are shared with our customers and the mutual approval process is initiated. After approval is received, the mass production phase is started. During the mass production process, CMM measurements are made on the selected sample products and the results are regularly recorded in the production process reports. This application ensures continuous quality control of the products and contributes to the high standards of each batch of production.

Advantages of CMM Technology:

• High Precision: CMM machines measure with millimeter precision and check whether the products are fully compliant with technical specifications.

• Efficiency and Speed: Automatic measurement processes provide detailed quality control without slowing down production speed. This increases efficiency and ensures quality.

• Detailed Reporting: Measurement results are presented with colorful visuals and detailed reports, so that possible incompatibilities can be quickly detected and necessary corrections can be made.

All of these processes allow us, as Teknika Plast Endüstriyel, to continue to provide our customers with reliable, high-quality and highly accurate products.