Laser Mold Welding

Laser Mold Welding

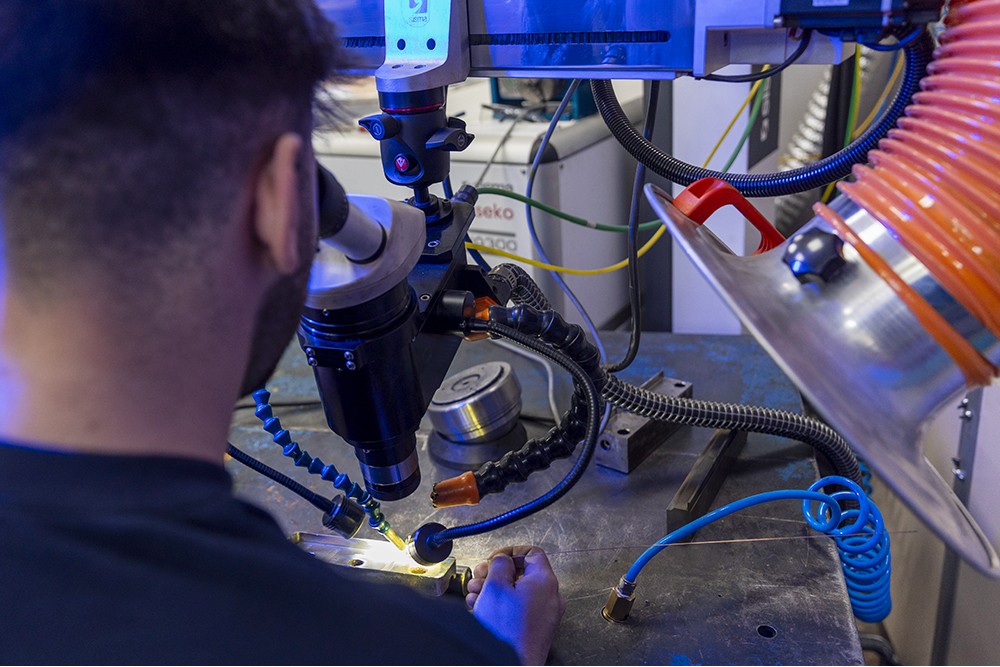

One of the most important features in plastic part production is that we have mold and machine maintenance teams within our own organization. Teknika Plast offers high precision solutions in the repair and reuse processes of molds by using Laser Mold Welding technology. Laser mold welding is a method applied for the repair of broken or worn mold surfaces. This process is done by selecting special wire according to the steel properties and hardness of the molds. The welding process performed with laser technology protects the material properties with minimal heat effect, thus achieving high surface quality. Our mold maintenance team quickly repairs and revises molds that require maintenance or emergency intervention thanks to the regular checks it performs. In this way, it ensures continuity in production processes, extends mold life and reduces costs. Laser mold welding offers an economical and efficient solution especially for businesses that manufacture and repair molds. In addition, thanks to this technology, Teknika Plast manages mold maintenance processes more efficiently, quickly and precisely. Teknika Plast, which also has an active spare parts warehouse for machine maintenance, performs regular maintenance of its machines. Thanks to these systems, interruptions in production processes are minimized and efficiency is increased.