Hotstamp

Hotstamp

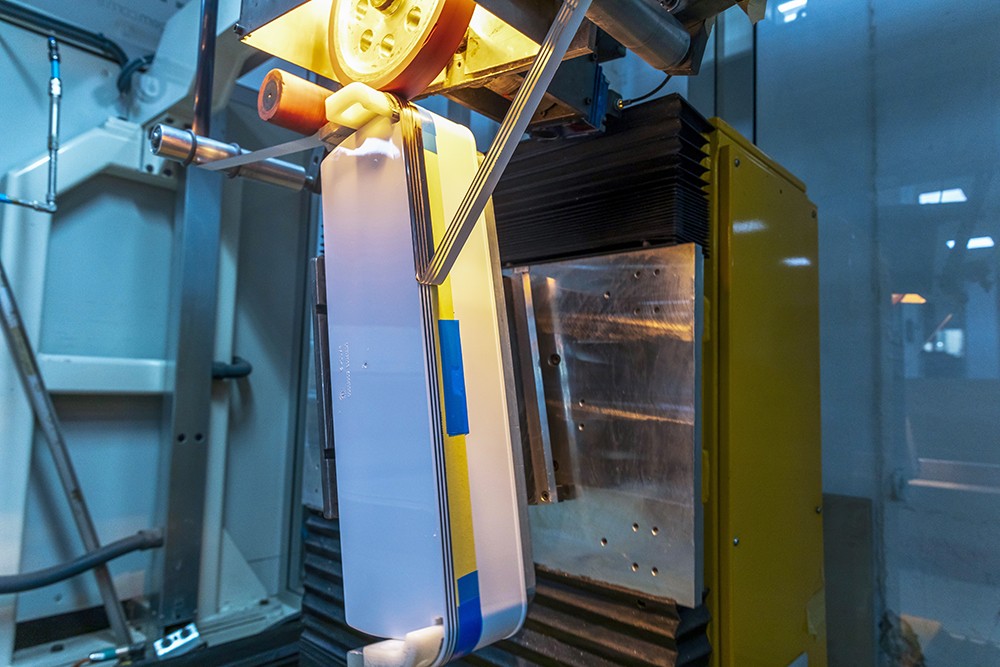

The machines we use in our Hotstamp (Hot Stamping) department, thanks to their 3-axis operation, allow us to achieve perfect results even on oval or sharp-cornered products. In fact, our Teknika Plast engineers have designed and developed our own hotstamp machines. Without using chemicals or paint, the foil is thermally bonded to the surface to be coated.

Clean Room technology is also used in this production area. The clean room controls the air quality and ensures that dust and foreign particles are kept at a minimum level. In this way, the hot stamping process is carried out with high precision and perfect injection results are always achieved in our products.

Hot Stamping Foils

- Metallic Foils: The foils we use to give plastic surfaces a stylish metallic look offer options in different metallic tones and matte levels such as stainless steel, nickel, antique gold and copper. These foils add elegant aesthetics to products, providing an original and premium look.

- Brush Patterned Foils: Foils that add elegance with non-conductive, elegant brush patterns give your products a modern and sophisticated look. They add rich details in terms of aesthetics.

- Aluminum Look Foils: Aluminum look foils containing gold and metallic tones give plastic products a metal feel, while also offering variety with colorful and shiny metal tones. These foils add an aesthetic and elegant touch to the design, providing a high-quality look to your products.