IMD - ESD - Clean Room Technology

IMD – ESD – Clean Room Technology

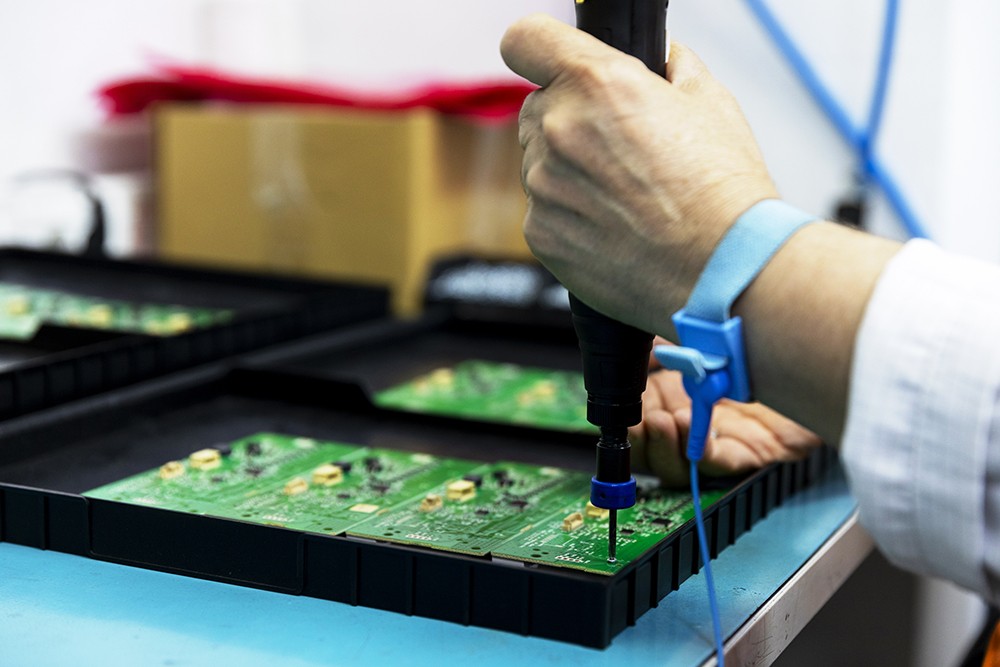

Teknika Plast produces high quality and safe products by using IMD (In-Mold Decoration) and ESD (Electrostatic Discharge) technologies together. IMD combines aesthetics and durability, allowing decorative designs to be integrated with plastic parts. ESD technology, on the other hand, guarantees the protection of electronic components from static electricity, thus increasing the safety and life of the products. Teknika Plast produces products that offer aesthetics, durability and safety at the same time by integrating both technologies.

IMD-ESD Molding

Teknik Plast also designs and manufactures molds for parts produced in the IMD and ESD departments, thus ensuring full control from mold production to the final product and maintaining high quality standards. These production areas consist of closed areas with special ventilation systems known as “Clean Rooms”. Clean room technology provides sterile environments with special air filtration and pressure control systems to minimize dust and particles in the air. In this way, IMD and ESD production processes that require high precision are carried out in the cleanest and safest environment.